Elastomer Bonding – A Flexible and Robust Method for Joining Parts

BONDING WITH ELASTIC MATERIALS

When bonding with elastomers, an elastic material – often an elastomer – joins two or more parts. Our bonding specialists at FHR offer you innovative solutions that raise the precision and performance of your products to a new level. Learn more about elastomer bonding and how you can benefit from our expertise in this bonding process.

Our bonding service – The solution for your demanding projects.

How It All Works

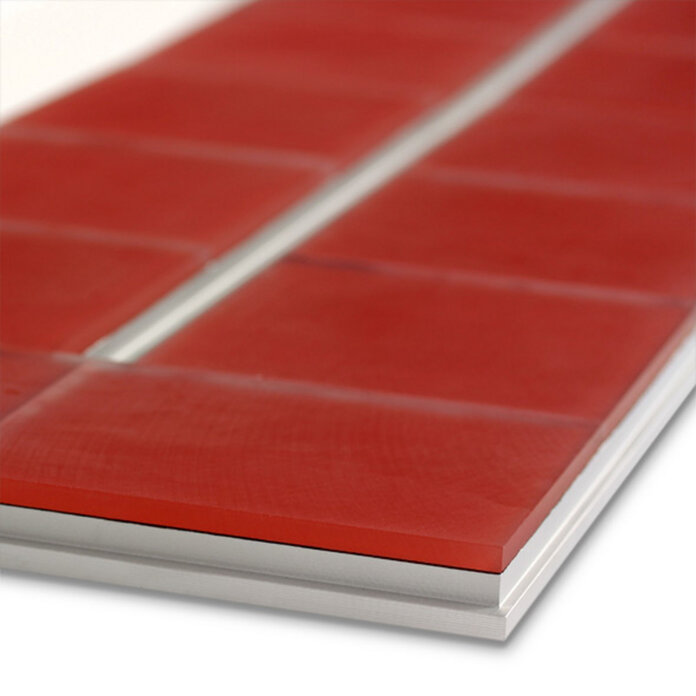

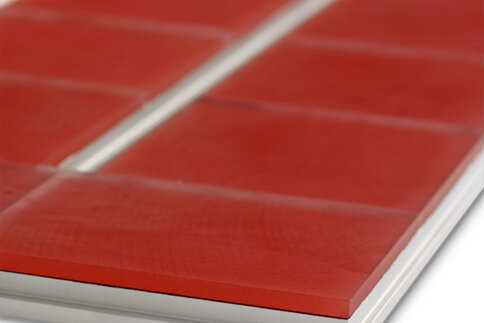

Elastomer Bonding for Flexible Connections

When bonding with elastomers, an elastic material – often an elastomer – joins two or more parts. The elastomers can contain additives as an option to ensure electrical conductivity.

Bonding creates a solid and durable bond that lasts even under extreme conditions. The fact that elastomers can be used on various surfaces and for different applications – from electronics to components in the automotive industry – means that the process is highly versatile.

A particular advantage of this bonding process is that it is carried out at room temperature. This prevents the occurrence of mechanical stresses in the bond after joining, which could otherwise be caused by different thermal expansion coefficients of the target and backing plate at higher temperatures. Therefore, this method suits target composites exposed to high mechanical loads. At the same time, the elastic properties of the elastomer allow a certain amount of movement between the connected parts, which is why this bonding process is also used for components exposed to vibrations or thermal fluctuations.

Special properties of Elastomer bonding

- Adequate ductility (plastic deformability) of the elastomer to compensate for mechanical stresses

- Low/lower thermal conductivity

- Electrical conductivity depending on the additives added, from insulating to highly conductive

We’ll Handle It for You

Our Bonding Process at a Glance

Epoxy Bonding

In this process, the materials are bonded using epoxy resin. Also possible at room temperature.

Nano Bonding

A nano-reactive film is used to join the materials together at room temperature to form a target composite.

Metallic Bonding

Bonding with metallic materials and indium as soldering material.

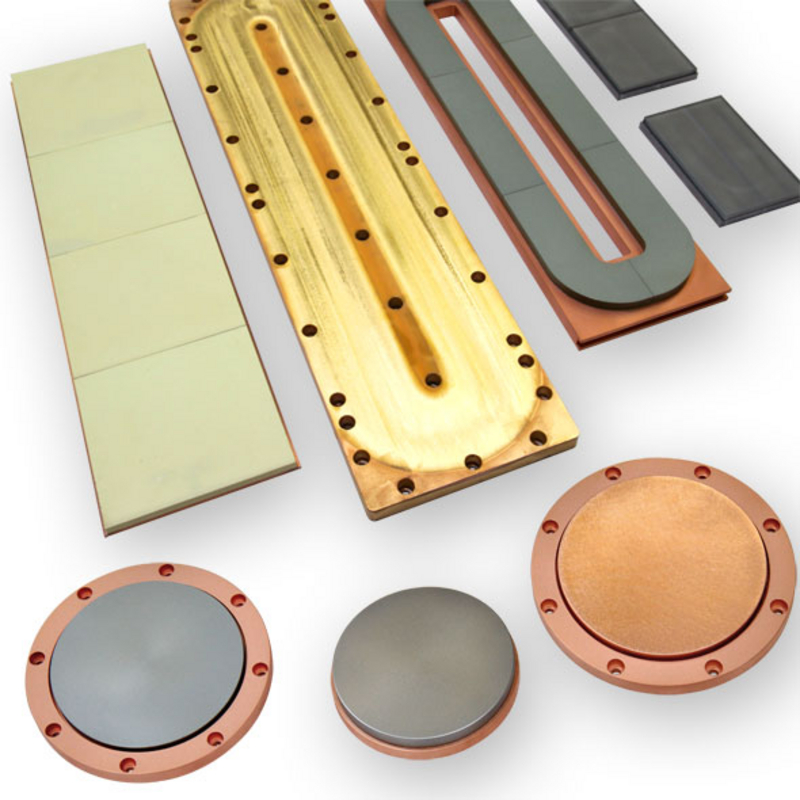

We Manufacture Sputtering Targets in All Materials and Shapes

Are you looking for the right target for your coating system? FHR develops and manufactures sputtering targets up to 4000 mm target length according to customer requirements – large series and individual items.

Simply enquire, and we will discuss everything with you in a personal consultation.

Why FHR for Your Bonding Project?

Together into the future of material bonding with FHR:

- Outstanding quality: Our joining technology ensures outstanding results and durability.

- Customized solutions: We develop custom bonding processes to meet your unique requirements.

- Innovative Approaches: We are at the forefront of bonding technology, setting new standards.

- Dedicated customer service: our dedicated team is here to answer your questions and successfully implement your projects.

Explore the many possibilities our bonding technology offers and trust FHR as your trusted partner for outstanding bonding solutions. Contact us today to learn more and realize your visionary projects together.

Your Contact Person

Do you have any questions?

Karsten Kleber, our materials accountant, is at your service. Send us an email or simply give us a call and let our experts assist you.