CONFORMAL COATINGS ON ALL GEOMETRIES

Atomic layer deposition (ALD) is a specialized cyclic CVD process known for its ability to deposit highly conformal surface coatings with unprecedented precision in terms of coating thickness.

- Cyclic CVD process

- Enables surface-conforming, precise coating thicknesses

- Use in semiconductor electronics and optics

Thanks to these unique properties, ALD has become an indispensable instrument in semiconductor electronics and optics. In particular, in applications where atomic-level control and uniform coverage are critical, ALD offers solutions that would be difficult to achieve with conventional deposition techniques.

Find out more about this reliable and precise technique in thin film technology.

How It All Works

HOW THE ATOMIC LAYER DEPOSITION WORKS

Atomic layer deposition (ALD) is a technique for applying very thin coatings to surfaces. This process belongs to the family of CVD methods. With ALD, the coating is formed by repeated, cyclical reactions on the surface.

This method is primarily used in semiconductor electronics, for example, to create special coatings in certain transistors. However, the technology is also used in other areas – such as the production of small mechanical systems, barrier coatings, or optical coatings.

In contrast to typical CVD processes, in which the chemical reaction takes place everywhere in the room, the reaction with ALD only takes place directly on the surface. It concerns a step-by-step process: First, a substance is applied to the surface, where it reacts. This substance is then removed, and another substance is applied, which reacts there again. This is repeated until the desired coating thickness is achieved. The chamber is cleaned after each step. Only a very thin film is deposited in each of these cycles. Thanks to ALD, uniform, very thin coatings can be produced on complex surfaces. This is achieved at relatively low temperatures of between 150 °C and 400 °C. Sometimes, special techniques or materials are used to reduce the required temperature even further.

The primary area of application was (and remains) semiconductor electronics, for example, the production of High-k-Gate coatings in MOSFETs. However, the advantages of ALD technology are also increasingly being utilized in other sectors – including the production of MEMS, barrier coatings, optical coatings, or functional coatings on particles or in capillaries.

Atomic layer deposition offers several advantages over other thin film deposition techniques:

- Atomic precision: ALD enables the deposition of materials, coating by coating, allowing precise and controlled coating thicknesses to be achieved at the atomic level.

- Surface conformity: The ALD process ensures excellent coverage, even on structured or highly topographical surfaces, thereby resulting in uniform and homogeneous coatings.

- Low processing temperature: Many ALD processes can be performed at temperatures lower than other CVD processes, rendering them suitable for temperature-sensitive substrates.

- Wide choice of materials: ALD can be used on a variety of materials – including metals, oxides, and nitrides, making it versatile for a wide range of applications.

- High levels of quality and purity: Thanks to the sequential process of ALD, high-purity coatings with minimal defects or impurities are produced.

- Scalability for industrial applications: Despite its atomic precision, ALD can be efficiently scaled for use in industrial production environments, especially in semiconductor electronics.

Thanks to these properties, ALD has established itself as a key process in many areas of materials science and technology.

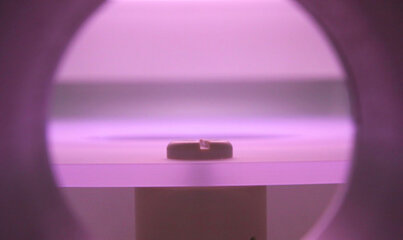

FHR designs and builds ALD coating systems according to the specific requirements of our customers. Everything can be customized – from the configuration of the chamber to the heating and cooling methods. The range includes platforms for 100, 150 and 300 millimetres, as well as ALD modules for integration into cluster systems. In addition, customized systems based on ALD technology are also possible.

Vacuum coating systems

Discover how our vacuum coating systems form the basis for high-performance coatings in numerous industries, and how our technologies can be used for your projects.

Other technologies and coating processes

FHR – The Right Partner at Your Side

Shaping the future together – with reliable and high-quality coating solutions from FHR:

- Industry-leading quality: Our vacuum coating systems are designed for maximum precision and durability.

- Customized solutions: We offer individual solutions for your coating project that meet your specific requirements.

- Innovative methods and technologies: With our many years of experience and expertise in vacuum coating, we continue to set new standards.

- Dedicated customer service: Our experienced team is always available to answer your questions and provide you with support in your projects.

Discover the diverse range of possibilities with our vacuum coating technology, and place your trust in FHR as your reliable partner for outstanding coating solutions. Please feel free to get in touch with us to find out more and realize your projects together.

Your Contact Person

Do you have any questions?

Would you like to discover more about thin film technology or receive general advice on our vacuum coating systems and our coating service? Then feel free to get in touch with us – our team of experts will be happy to answer all your questions.