FHR AS A COMPANY

Get to know FHR – Your experts in

thin film technology

Pioneers in Thin Film Technology

FHR Anlagenbau GmbH

We are experts in translating unique requirements into robust production systems and processes.

A Vital Group Company

We are FHR

A group of dedicated engineers from Dresden, with many years of experience in thin film and microsystems technology, founded FHR Anlagenbau GmbH in 1991 with the aim of implementing modern, functional coatings in customized concepts.

Today, we are The Thin Film Company.

THE ENGINE BEHIND OUR GROWTH

Our customer base has grown steadily since our pioneering days more than 30 years ago and includes well-known, high-caliber manufacturers, as well as small and medium-sized companies that nevertheless maintain a leading global position in their industry.

Even during the earliest development phases of products and processes, industrial and academic researchers and developers rely on our innovation and expertise in the field of functional coatings, and regularly present us with new challenges.

Our Core Competencies

What we do

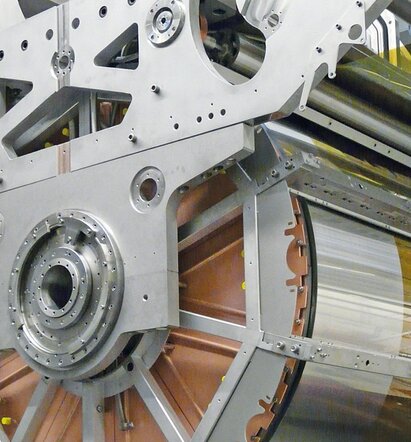

Then, as now, our roots lie in the field of customized coating system technology. To date, we have already supplied more than 300 coating system platforms, thereby enabling us to draw on a large number of tried-and-tested assemblies that have proven effective in practice.

- We develop comprehensive production systems that are adapted to our customers’ applications.

- We handle the pre-production qualification process for you, or work with you to develop material compositions for the consumables (sputtering targets) in our systems that are specifically tailored to your requirements.

- A professional service and consultation are naturally part of our range of services, and round off our portfolio.

Engineering

The development of tailored systems is just as much a core competence for us as the derivation of system platforms and their implementation in series systems. The unifying feature of all our systems is the deposition of functional coatings in a vacuum.

Our aspiration

We make new findings from research and development usable for industrial applications – that is our mission. We follow this path together with our customers, starting with layer stack development, through implementation in pilot plants to scaling up on an industrial scale.

Our expertise lies in embracing individual customer requirements and developing in tandem a coating system tailored to the application. We combine an expert knowledge of process technology with mechanical design, software development and automation. The key to success here is to design individualized systems in such a way that they can be used to manufacture competitive products.

We have developed extensive process engineering expertise in various technologies. These include:

- Reactive and non-reactive magnetron sputtering

- Vacuum vaporizing

- CVD and PECVD to facilitate the efficient deposition of metals, oxides and nitrides

- Atomic Layer Deposition (ALD) for creating ultra-thin functional coatings with a homogeneous layer thickness on complex 3D surface structures

- Plasma-assisted etching technologies for surface treatment and extremely efficient material removal (high-rate etching)

The result is stable processes suitable for production. We are only satisfied when our customers can produce functional coatings to the desired quality.

Expertise in handling materials is crucial for the production of high-performance functional coatings on different substrates.

That is why we not only offer the equipment, but also the necessary consumables. For example, we develop and manufacture sputtering targets by experts who understand that the structure and grain size of the initial material can have an influence on the quality of functional coatings, and, therefore, on our customers’ products.

We manufacture and develop sputtering targets precisely to your requirements.

Your Contact Person

Do you have any questions?

Do you have questions and want personal advice? Get in touch with our Marketing Team – we will be happy to help you.

CAREER AT FHR ANLAGENBAU

With many years of know-how and creativity, we develop new technologies and innovative plant engineering that drive our customers forward - quality is our strength.

As a leading company in the field of vacuum coating technology, we offer you exciting career prospects in an attractive working environment. We are looking for creative minds who will advance us and our customers. Whether you are an electrician, a project manager or a commercial employee: You too can become part of our team.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/9/d/csm_03-FHR.Roll.1600-Folie_bff23219b1.jpeg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/6/csm_fhrroll300-1200px-1_ffd9789224.jpg)