Flexible CIGS Solar Cells – Production

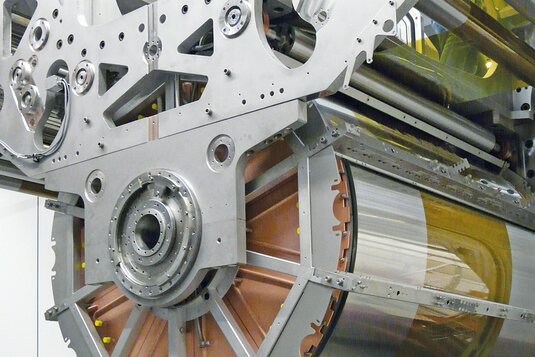

Roll-to-roll production system for the deposition of CIGS solar cells on films

APPLICATION

Solar energy is not only free, but – with certain time restrictions – also available everywhere. Where prolonged disconnection from the power grid is unavoidable, solar cells are cheaper and lighter than carrying energy in the form of batteries or fuel, e.g. for stationary systems in remote locations, in mobile outdoor applications or in satellites. For installation on roofs that do not have the structural characteristics for heavy panels, or even tarpaulins, the solar cell must also be very light.

REQUIREMENTS FOR THE SYSTEM

A line of roll-to-roll systems will coat film with solar cells. The films are up to 1.6 m wide and up to 3 km long and require a metallic back electrode, a CIGS absorber layer and a transparent front electrode. While the electrodes are sputtered, the absorber layer must be produced by evaporation. The film must be heated to well over 200 °C in some cases for effective layer growth.

- High efficiency of the solar cell

- Low weight

- Cost-effective due to efficient mass production

SOLVING THE REQUIREMENTS

The line consists of four roll-to-roll systems, with the two sputtering systems (front and rear contact) and the two evaporator systems (absorber layer) each having a similar design. On all systems, the entire winding unit is extended on a large flange to ensure effective accessibility when inserting the belt. The technological units – sputter sources and evaporators – remain in the chamber. The systems are equipped with devices for spreading and guiding the film.

THE SPECIAL FEATURES OF THE FHR.Roll.1600

- Functional roll-to-roll production systems up to 1.6 m belt width as single units

- Combination of the thin film technologies – sputtering and evaporation

- Systems with up to three process rollers

- Highest material utilization and longest target service life through the use of tubular cathodes

- Temperatures sometimes well over 200 °C

Your Contact Person

Do you have any questions?

Would you like to know more about our FHR.Roll product range? Our expert, Sven Häberlein, will be happy to help you. Get in touch with us.