New Materials for Thin Layers

Combination coating system with PECVD, ALD and FLA technology for layer development

APPLICATION

CVD processes, for example, for the deposition of silicon nitride or polycrystalline silicon, are common in the semiconductor industry, but require temperatures above 400 °C. However, flexible electronics on plastic, temperature-sensitive components on glass or mechanical protective coatings on mirrors also require coatings that are as dense as possible – in some cases of high purity and with a defined crystal structure. The necessary reaction energy is, therefore, provided by a plasma (PECVD), highly reactive chemicals (ALD) or intense flashes of light (Flash Lamp Annealing – FLA), which only heat the surface, instead of temperature.

REQUIREMENTS FOR THE SYSTEM

The system will be used to research and develop new processes for layer deposition. The system is designed to enable PECVD, ALD and FLA on 100 mm wafers without interrupting the vacuum. It must also be possible to retrofit an additional process – e.g. sputtering. The footprint in the cleanroom is predefined – and very small. After all, the system must be able to complete complex formulas automatically, continuously record all process data and enable different user levels.

- Surface-conforming, dense coatings using PECVD and ALD

- Layer deposition far below standard CVD temperatures

- Density, purity and crystal structure like high-temperature coatings

SOLVING THE REQUIREMENTS

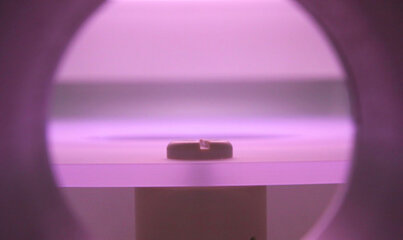

FHR.Star.100-ALD/PECVD/FLA (former cluster DS 100 x 4) consists of a small single substrate load lock with an integrated robot arm for loading the adjacent process chamber under vacuum. In the process chamber, the substrate lies on a rotating arm, which moves it under one of the four process stations and lifts it there. This isolates the process station from the rest of the process chamber and prevents it from being coated simultaneously. The precursor and gas supply are located above the system. The control cabinets belonging to the system, e.g. the capacitor banks for the flash lamps, are located in the basement. As is usual with FHR systems, this system has comprehensive automation with access to all components and convenient formula control.

THE SPECIAL FEATURES OF THE FHR.Star.100-ALD/PECVD/FLA

- Supports ALD, PECVD and FLA without vacuum interruption

- Minimum space requirements of only 1.8 m x 1.1 m

- Installation in the clean room

- Formula-controlled coating with monitoring of all system components and process data logging

Your Contact Person

Do you have any questions?

Would you like to know more about our FHR product range and individual application fields? Andreas Skivof, will be happy to help you. Get in touch with us.