Thin Film Photovoltaics on Wafers

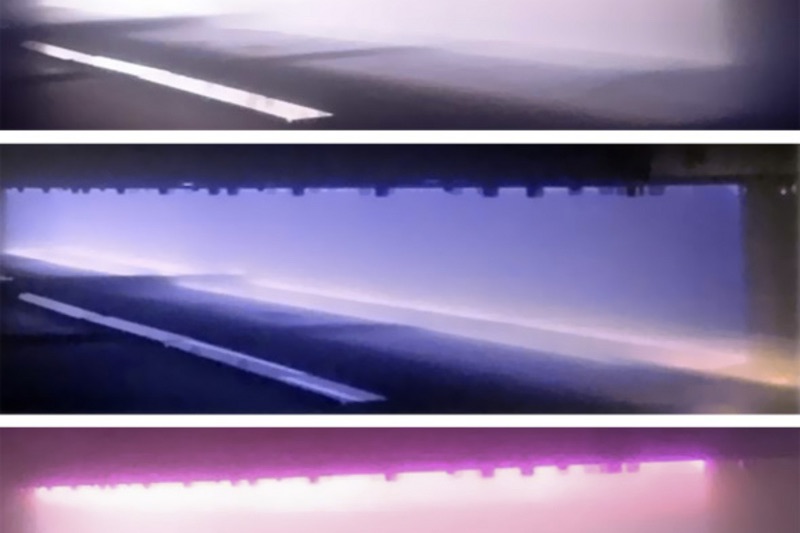

Sputter coating system for anti-reflective coatings

APPLICATION

Solar energy is not only free but – with certain time restrictions – also available everywhere. Where prolonged disconnection from the power grid is unavoidable, solar cells are cheaper and lighter than carrying energy in the form of batteries or fuel, e.g. for stationary systems in remote locations, in mobile outdoor applications or in satellites.

REQUIREMENTS FOR THE SYSTEM

The system is to be integrated into a line for the production of thin film solar cells on rigid substrates. Their task is to deposit an anti-reflective layer that reduces the reflection of sunlight on the outside of the solar cell and thus provides the solar cell with more light for energy generation. The layer stack consists of several dielectric layers that have to be applied by sputtering – in some cases, reactively. As part of a 24/7 production line, the system must independently remove the substrates fed to it from the carrier boxes and deposit them there again after coating.

- High efficiency of the solar cell

- Low material requirements

- Cost-effective due to efficient mass production

SOLVING THE REQUIREMENTS

Inline systems are ideal for such consistent production tasks with a high rate of throughput. FHR.Line.1100-V is a vertical inline system in which the substrates for coating are moved in an upright position past highly productive tube sputtering sources that are also oriented in an upright position. The individual substrates are provided in boxes, removed by a placement robot programmed by FHR and placed in large carriers (substrate holders). The inclination of the system by 7° to the vertical ensures that the substrates remain in the carrier. With a cycle time of < 8 minutes, the carriers pass through the system, where they are brought into the vacuum in several airlocks separated by valves, tempered, coated and released back into the atmosphere via an airlock. A carrier return system brings the carriers back to the assembly cell, where a second robot removes the substrates and places them back into transport boxes. The carrier is then reloaded by the second robot and used again. stem, where they are brought into a vacuum in several airlocks separated by valves, tempered, coated and released back into the atmosphere via an airlock. A carrier return system brings the carriers back to the placement cell, where a second robot removes the substrates and places them back into transport boxes. The carrier is then reloaded by the second robot and used again.

THE SPECIAL FEATURES OF THE FHR.Line.1100-V

- Use in a 24/7 production line

- Carrier transport – including return completely automated

- Automatic loading and unloading with FHR’s own control system

- Highest material utilization and longest target service life through the use of tubular cathodes

Your Contact Person

Do you have any questions?

Would you like to know more about FHR.Line product range? Our expert, Sven Häberlein, will be happy to help you. Get in touch with us.