Antibacterial coatings in medical technology

Surface coatings in medical technology

The requirements in medical technology are unique. From implantable devices to medical instruments – precision and quality are essential.

FHR Anlagenbau GmbH provides a wide range of processes and systems for this purpose. PVD coatings – produced by sputtering or vapor deposition – enable the surfaces of surgical instruments, implants and medical technology components to meet high-level requirements. Bio-compatibility, improved mechanical and optical properties, corrosion resistance to acids and alkalis or easy cleaning are typical requirements.

THE IMPORTANCE OF COATING SYSTEMS IN MEDICAL TECHNOLOGY

Coating systems play a decisive role in medical technology for several reasons:

The coatings help to increase the durability and service life of medical devices and instruments. This is particularly important, as many of these products are expensive and designed for long-term use.

The coatings help to increase the durability and service life of medical devices and instruments. This is particularly important as many of these products are expensive and designed for long-term use.

Coatings can be designed to be easy to clean and have antimicrobial properties. In medical technology, where hygiene is of crucial importance, these properties help to prevent infections and ensure the safety of patients and medical staff.

Thin film technology is often used in medical diagnostic devices and sensors to ensure maximum precision and accuracy. This is crucial for the accurate diagnosis and treatment of diseases.

Coatings can be environmentally friendly and help to conserve resources. Sustainable practices have become increasingly important in the medical technology industry.

Coatings enable the development of innovative medical devices and processes that improve healthcare. They contribute to the expansion of possibilities in medical technology and enable progress in the healthcare industry.

On balance, coating systems and thin film technology help to increase quality and safety in medical technology and optimize healthcare. They represent an integral part of modern medicine, and are used in numerous applications to offer patients better treatment options.

Insight into the Processes

THIN FILM SENSORS AND REFLECTOR COATINGS

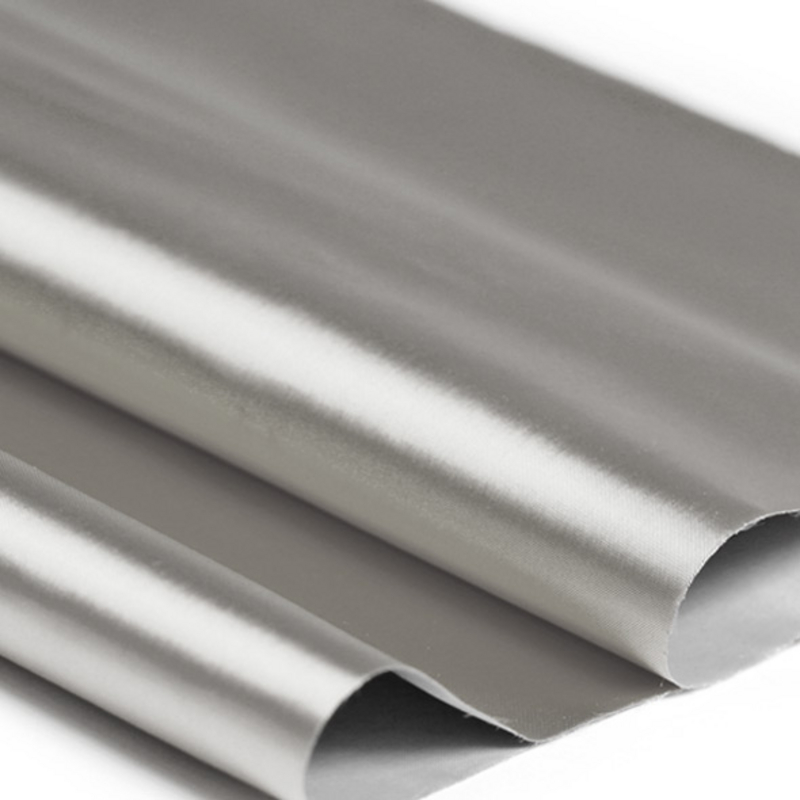

FHR’s systems and processes are used to manufacture thin film sensors and electronic components for medical technology, among other things. Precious metal coatings – especially silver – provide antibacterial properties for surfaces, such as catheters, implants or wound textiles. Copper coatings are used in hospital equipment.

Dark, matte PVD surfaces prevent optical reflections – important when using magnifying lenses and cameras.

Thin films also serve as optical filters for fluorescence microscopy and imaging techniques. Dielectric mirrors, for example, dental mirrors, are also produced using FHR coating technology.

Color coding can be achieved with the aid of PVD coatings. FHR also offers combined PVD and PECVD systems for the reflector coating of surgical lights.

FUNCTIONAL LAYERS

Our vacuum coating systems lend your surfaces unique capabilities.

FHR – The Right Partner at Your Side

Shaping the future together – with reliable and high-quality coating solutions from FHR:

- Industry-leading quality: Our vacuum coating systems are designed for maximum precision and durability.

- Customized solutions: We offer individual solutions for your coating project that meet your specific requirements.

- Innovative methods and technologies: With our many years of experience and expertise in vacuum coating, we continue to set new standards.

- Dedicated customer service: Our experienced team is always available to answer your questions and provide you with support in your projects.

Discover the diverse range of possibilities with our vacuum coating technology, and place your trust in FHR as your reliable partner for outstanding coating solutions. Please feel free to get in touch with us to find out more and realize your projects together.

Your Contact Person

Do you have any questions?

Daniel Oelsner will be happy to help you. Write us an e-mail or simply give us a call, and let our experts advise you.