27 Nov 2014

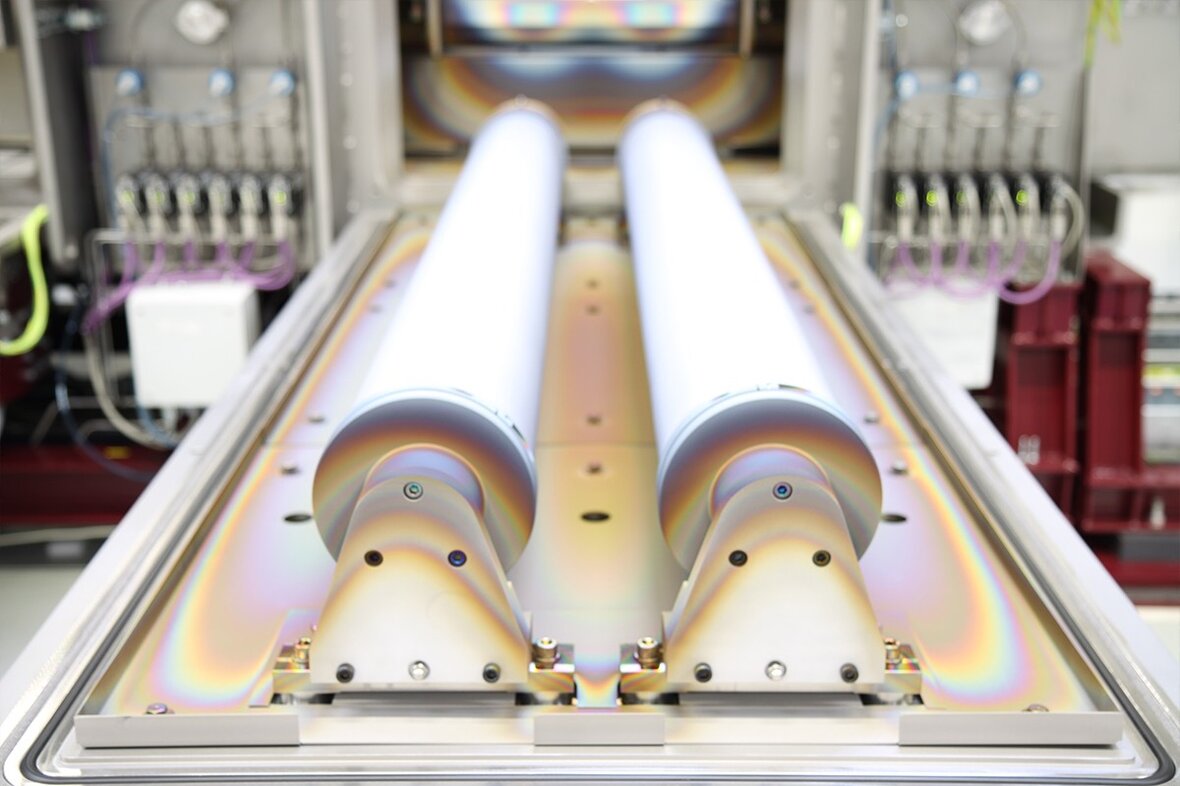

FHR provides third-generation tube coating solutions for solar thermal absorbers in concentrated solar power plants (CSP) – highly productive sputtering systems to deposit complex thin film systems on tube surfaces

In the world of solar thermal applications, functional layers are crucial. For solar receivers, optimal radiation absorption and minimal heat emission (IR radiation) are essential. These properties are achieved through a vacuum coating of the absorber tubes with a special thin-film system made of metallic and ceramic layers.

When it comes to functional layers for solar thermal applications, then greatest importance is attached to the best possible absorption of solar radiation while the emission of heat (IR radiation) shall of course be as low as feasible. These properties are achieved by way of coating the absorber tubes under vacuum with a special system of thin films consisting of metallic and ceramic layers. FHR Anlagenbau provides for the solar thermal energy market to their Taiwanese customer Xxentria tube coating solutions of the third generation which feature the physical vapour deposition technology (PVD). These cutting-edge, highly versatile and productive vacuum coating systems of the FHR.Line series are ideally suited for tube diameters ranging from 25 mm to 100 mm. The types of magnetrons used can be chosen freely and the sputtering targets can be arranged in an appropriate way, which makes for customer-specific optimisation of the sputtering configuration with view to both layer system and tubular geometry of the substrates. An absorptance of more than 95 per cent and lowest emissivity can already be achieved with an inexpensive standard layer system deposited on the absorber tube surfaces.