Decorative coatings with different properties

Decorative coatings combine aesthetics with function. They are used in a wide range of industries – from the automotive industry, where they provide eye-catching body colors, to interior design and the fashion industry. These coatings offer far more than just visual appeal. They often offer additional protection against abrasion, corrosion, and UV radiation. Their ability to combine beauty with durability makes them an indispensable component in many product designs.

Discover more about the possibilities of decorative coatings.

What We Offer

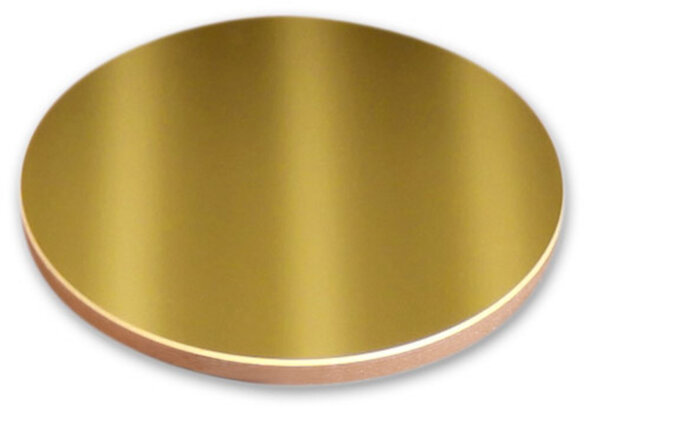

Metallic effect coatings

Using techniques such as magnetron sputtering or thermal vapor deposition, surfaces can be embellished with decorative metal coatings. In the PVD vacuum process, you have the choice between matt and glossy metal coatings. Our color palette ranges from dark tones – such as black and blue, to light colors, such as gold and silver. In order to preserve the shiny appearance of these metal coatings, they are often protected with a transparent oxide coating.

Typical effect metals

- Chromium (Cr)

- Ruthenium (Ru)

- Copper (Cu)

- Gold (Au)

- Silver (Ag)

DIELECTRIC EFFECT COATINGS (INTERFERENCE COLORS)

Transparent oxide coatings that are thicker than half the length of the light (d > λ/2) can reflect the light at their edges in such a way that impressive color changes occur. Depending on the coating thickness, colors reminiscent of a rainbow can be created.

For special reflections or light transmission, in addition to color effects, you can combine different dielectric materials. This allows you to achieve exactly the desired result.

Examples of reactive sputtered oxides:

- Silicon oxide (SiO2)

- Titanium oxide (TiO2)

LOOKING FOR A SPUTTER TARGET?

We develop and manufacture sputtering targets up to 4000 mm target length as required – both in large series and as individual items.

FHR – The Right Partner at Your Side

Shaping the future together – with reliable and high-quality coating solutions from FHR:

- Industry-leading quality: Our vacuum coating systems are designed for maximum precision and durability.

- Customized solutions: We offer individual solutions for your coating project that meet your specific requirements.

- Innovative methods and technologies: With our many years of experience and expertise in vacuum coating, we continue to set new standards.

- Dedicated customer service: Our experienced team is always available to answer your questions and provide you with support in your projects.

Discover the diverse range of possibilities with our vacuum coating technology, and place your trust in FHR as your reliable partner for outstanding coating solutions. Please feel free to get in touch with us to find out more and realize your projects together.

Your Contact Person

Do you have any questions?

Our Director Product Management Sven Häberlein is at your service. Send us an email or simply give us a call and let our experts give you advice.