COATINGS IN ENERGY TECHNOLOGY

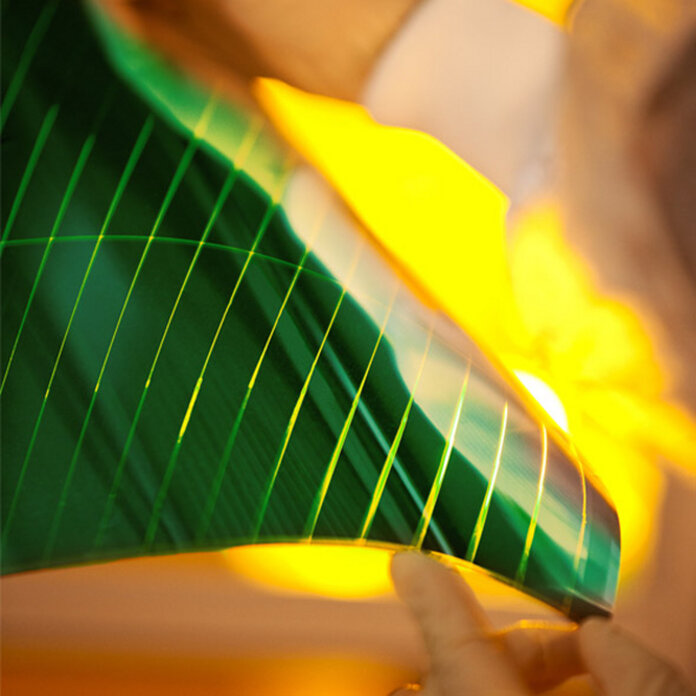

PHOTOVOLTAICS – COATING MATERIAL FOR SOLAR CELLS

FHR stands for cutting-edge technology in solar cell production. We supply you with advanced production technology and coating materials for thin film PV, c-Si PV, organic PV, PVSK and much more. Our automation expertise – including robot-assisted wafer placement – maximizes your productivity.

We are experts in the field of CIGS technology for glass and flexible substrates. Our FHR.Line and FHR.Roll product ranges – for coating widths of up to 2,500 millimeters for flat substrates and 1600 millimeters for flexible substrates, respectively – have been proving their worth in the industry for years.

We are also setting new standards in the production of thin film solar cells based on amorphous silicon (a-Si) and gallium arsenide (GaAs).

From front to back contact

Versatility within the FHR portfolio: From TCO to organic solar cells

FHR offers you a broad spectrum: Our technologies range from the deposition of the front contact from transparent, conductive oxides (for short: TCO) – to systems for photoactive absorbers made of copper, indium, gallium, selenium or doped a-Si:H and the production of metal back contacts.

With the world’s first production system, we are seen as pioneers in the vacuum-based production of organic solar cells. Our roll-to-roll system enables the coating, structuring and laminating of flexible substrates under vacuum – a world first.

Vacuum Systems for the Production of New Types of Batteries

BATTERY/ACCUMULATORS

FHR – Pioneers in thin film battery technology

Vacuum coating systems are essential for advanced batteries and rechargeable accumulators. FHR remains at the forefront of this development. We manufacture all components as thin films – from the anode and cathode to the electrolyte. Our technology enables efficient and cost-effective production, especially for thin film batteries, with PVD processes using the roll-to-roll method. FHR develops customized solutions from FHR.Roll product range for this purpose.

We are also experts in sputtering and vapor deposition of lithium, which is crucial for high-energy density lithium-ion and solid-state batteries.

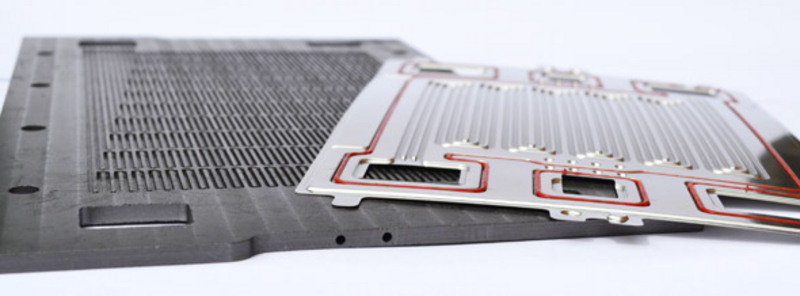

Coating of Metallic Bipolar Plates

Fuel cells

FHR is setting new standards in the manufacture of fuel cells. Our systems coat metallic bipolar plates. These thin layers protect against corrosion while improving electrical conductivity and heat dissipation. They are also crucial for the electrolysis of water to hydrogen in the “power-to-gas” process.

FHR as the Market Leader

SOLAR THERMAL

FHR is the market leader in solar thermal energy. Our technologies produce selective absorbers and mirrors for CSP solar thermal power plants (“solar receiver tubes”). We specialize in tube coating for parabolic trough collectors. Our selective absorber layers with a metal-ceramic structure are resistant to high temperatures.

They function on the outside like a light trap for sunlight and on the inside like a heat mirror – the absorbed energy is taken up by the heat transfer fluid and passed on to a turbine.

FUNCTIONAL LAYERS

Our vacuum coating systems lend your surfaces unique capabilities.

FHR – The Right Partner at Your Side

Shaping the future together – with reliable and high-quality coating solutions from FHR:

- Industry-leading quality: Our vacuum coating systems are designed for maximum precision and durability.

- Customized solutions: We offer individual solutions for your coating project that meet your specific requirements.

- Innovative methods and technologies: With our many years of experience and expertise in vacuum coating, we continue to set new standards.

- Dedicated customer service: Our experienced team is always available to answer your questions and provide you with support in your projects.

Discover the diverse range of possibilities with our vacuum coating technology, and place your trust in FHR as your reliable partner for outstanding coating solutions. Please feel free to get in touch with us to find out more and realize your projects together.

Your Contact Person

Do you have any questions?

Daniel Oelsner will be happy to help you. Write us an e-mail or simply give us a call, and let our experts advise you.