Precise control of alloy coatings

Confocal sputtering is a revolutionary technique in coating technology, especially with regard to research and development involving Star systems. This method can reduce costs for targets, as up to five different materials can be used in a single chamber. In addition to this, integrated co-sputtering offers the flexibility to create diverse and customized coating compositions, which renders the process both economical and advantageous from a technological standpoint.

Find out more about this reliable and precise technique in thin film technology.

How It All Works

What is behind confocal sputtering?

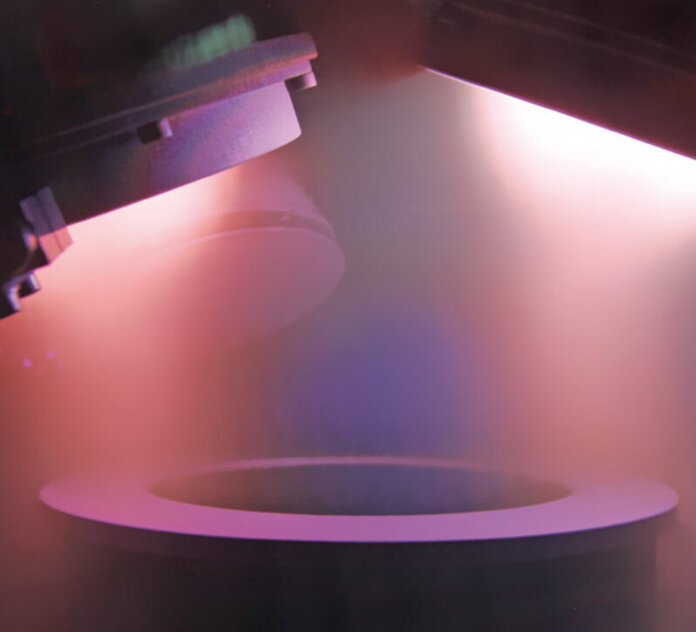

In conventional Star systems, the substrate is located directly under a sputter source. In order to ensure that the coating has the same thickness everywhere, this source must be significantly larger than the substrate. But there is also another method: The substrate can be rotated in the system and coated by smaller sources positioned at an angle.These sources are all aligned to a point directly under the substrate.

This is known as “confocal sputtering”. This is particularly practical for research and development purposes. With several such sources, different materials can be applied to the substrate at the same time without interrupting the vacuum in the system. This does not require much space in the laboratory. It is also possible to mix different materials to create a variety of coatings.

And another plus point: The required targets are much smaller and, therefore, more cost-effective, especially for expensive materials such as gold or platinum.

However, the classic method with just one source also has its advantages: The coating process is faster, and the distance between the source and substrate can be flexibly adjusted. The coating is very smooth, even with very thin coatings. With this turning method, the angle at which the material hits the surface is important to ensure the coating thickness’ uniformity.

Take a look at our Star systems that utilize both methods. Should you have any questions, our specialized experts from our system sales division will be happy to assist you.

Confocal sputtering offers numerous advantages over other thin film deposition techniques:

- Several materials in one chamber: Confocal sputtering allows up to five different materials to be placed in a single chamber, reducing process complexity.

- Cost efficiency: By utilizing several materials in one chamber, the costs for separate targets and the associated process set-ups can be reduced.

- Flexible coating composition: Thanks to the integrated co-sputtering approach, researchers and engineers can precisely control and customize the coating composition, thereby enabling a wide range of coating properties.

- Optimum utilization of Star systems: The process is particularly suitable for research and development using Star systems and optimizes their potential.

- Time efficiency: As several materials are simultaneously available in one chamber, coating processes can be carried out more quickly and efficiently without having to switch between different targets.

- Innovative material combinations: Confocal sputtering enables the development of new material compositions and structures that would otherwise be difficult to achieve with conventional sputtering techniques.

Confocal sputtering is an attractive option for many applications in modern coating technology.

Vacuum coating systems

Discover how our vacuum coating systems form the basis for high-performance coatings in numerous industries, and how our technologies can be used for your projects.

FHR – The Right Partner at Your Side

Shaping the future together – with reliable and high-quality coating solutions from FHR:

- Industry-leading quality: Our vacuum coating systems are designed for maximum precision and durability.

- Customized solutions: We offer individual solutions for your coating project that meet your specific requirements.

- Innovative methods and technologies: With our many years of experience and expertise in vacuum coating, we continue to set new standards.

- Dedicated customer service: Our experienced team is always available to answer your questions and provide you with support in your projects.

Discover the diverse range of possibilities with our vacuum coating technology, and place your trust in FHR as your reliable partner for outstanding coating solutions. Please feel free to get in touch with us to find out more and realize your projects together.

Your Contact Person

Do you have any questions?

Would you like to discover more about thin film technology or receive general advice on our vacuum coating systems and our coating service? Then feel free to get in touch with us – our team of experts will be happy to answer all your questions.