VMET – ACHIEVING GLOBAL LEADERSHIP WITH EFFICIENCY AND EXPERIENCE

In-depth expertise and experience in thin film technology working hand-in-glove with maximum production efficiency

THE VERY BEST IN THIN FILM TECHNOLOGY

We combine outstanding production performance with technical precision, and utilize our synergies as part of the Vital Materials Group, in order to become the leading supplier of vacuum coating systems and materials for an array of high-tech industries. Together with VMET, we envision a future in which we drive global advancements in thin film technology as the international market leader.

Why not take a look at VMET – where an ongoing commitment to innovation and excellence is firmly anchored in every action.

Shaping the future

OUR CONTRIBUTION TO INNOVATIVE TECHNOLOGIES

VMET is our partner for the efficient production of thin film coating systems in China. In a collaborative spirit, we are focussing on the modular design of our durable and future-centric production systems.

As part of the VITAL Group, we pursue one goal together with VMET: we combine production efficiency and expertise with unique technological know-how. We have made it our mission to change the world through innovative thin film technologies. We not only channel our focus on innovation with over 30 years of experience involving highly efficient functional coatings, but also on fostering respect and effective collaboration.

With nearly 340 employees at VMET, the production facility in Xuzhou has been fully operational since its commissioning in 2021. On request, we can manufacture your system there entirely according to your requirements and European standards.

Our strengths represent the basis of your success

- 14,000 m2 production area

- 10,000 m2 of space dedicated to research and development

- Maximum chamber size up to 180 m3

- Production lines 80 meters in length are possible

- Modular systems to match your requirements

We offer you the most efficient solution for your application

VMET is our partner for the production of modular thin film coating systems for a wide range of end applications, for example, within energy technology and microelectronics. Contact us and discover more about your available options.

Our systems at a glance

DISCOVER OUR PORTFOLIO

FHR.Line.1500.H

This carrier-based, horizontal magnetron sputtering system enables the production of thin film solar modules, sensors and functional glass. It offers a wide range of coating options.

FHR.Line.1500.V7

Typical machine platform for large-area coatings with carrier and vertical magnetron sputtering system. Among other things, it is used for the production of thin film solar modules.

FHR.Roll.1600

This roll-to-roll system offers a wide range of coating options for flexible substrates – especially plastic films. The system enables both high throughput and efficient production. Flexible films with a web width of up to 1.6 m can be provided with optical or functional coatings, metallisation and more.

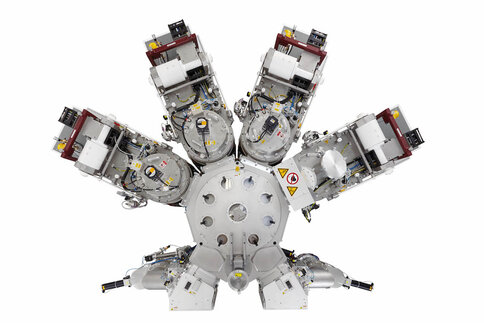

FHR.Star.150

These cluster systems are ideal for research and development purposes, as well as the production of small series in the semiconductor industry. Confocally arranged sources enable uniform coatings on substrates up to 200 mm, such as wafers, chips or blocks.

FHR.Star.300

Cluster vacuum coating system, ideal for research and development and small batch production. It is deployed in semiconductor technology for the development of sensors, MEMS or small functional electronics. It offers uniform coatings on substrates up to 200 mm – such as wafers, chips or blocks.

FHR.Star.300x400-SALD

Spatial Atomic Layer Deposition (SALD) systems enable uniform (and extremely dense) coatings with high deposition rates. The machine combines the advantages of ALD coating with highly efficient processes. It can accommodate substrates up to 300 × 400 mm in size.

FHR.Star.500- & 600-EOSS®

The FHR.Star.500-EOSS® platform is designed for the deposition of high-precision and clean coatings on substrates – such as wafers or optical glass. This technology enables the production of accurate optical filters. Substrates with a diameter of up to 200 mm can be coated with this series. Up to 300 mm are possible with the 600-EOSS® series.

Get to know us

Our experts will be happy to advise you

Feel free to reach out to book your consultation, so that you can take your application to the next level. Our team will be happy to assist.