24 Sep 2012

FHR introduces highly productive CIGS foil coating solutions for the photovoltaics industry and presents outstanding results in layer deposition of transparent electrodes (TCO)

So far, FHR Anlagenbau GmbH has delivered twelve coating systems for CIGS applications worldwide. These have been mainly used for research purposes and pilot productions.

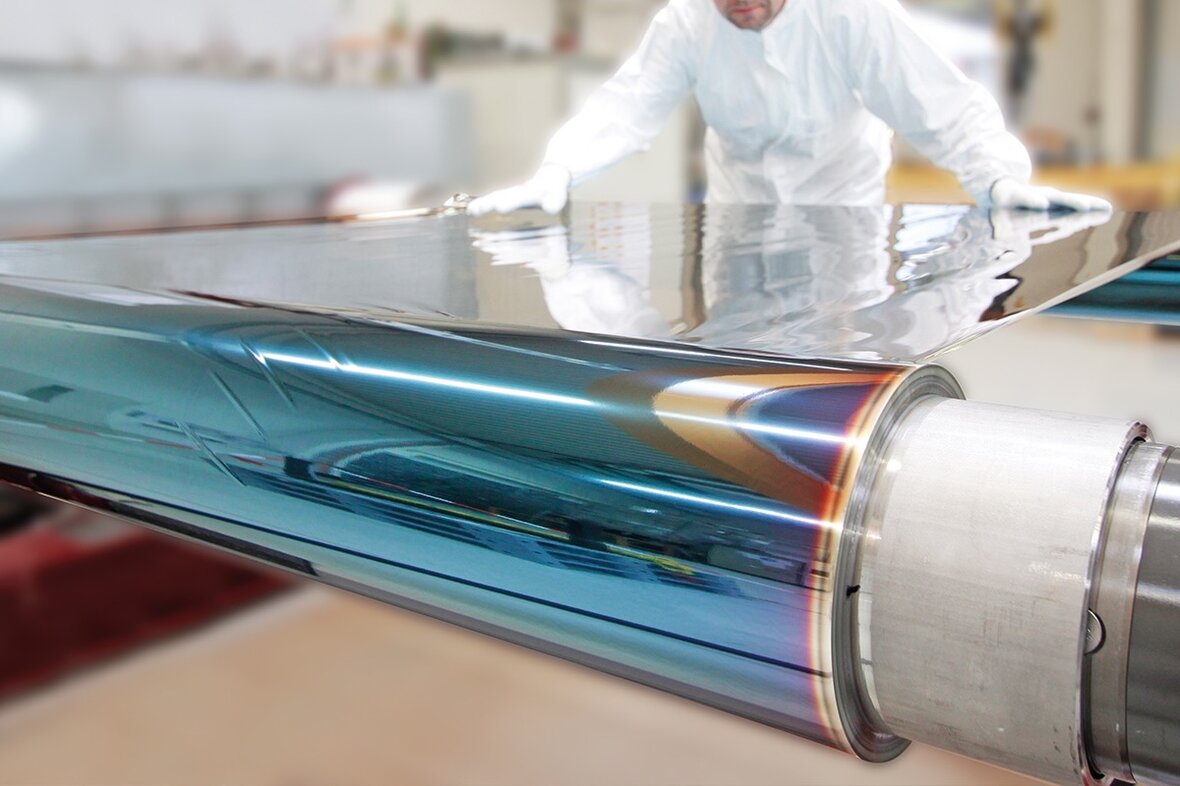

After shipping 12 CIGS coating systems mainly for R&D purposes and pilot lines worldwide, FHR Anlagenbau currently commissions roll-to-roll foil coating systems that achieve throughput and competitiveness comparable with highly productive CIGS deposition systems for glass substrates. Optimally adjusted sputter and evaporation processes allow stable characteristics of thin back contact, absorber and front contact layers along deposition width and length spanning several kilometers. Currently, operating time is only limited by available reel length of highly temperature-stable plastic foil.The transparent conductive electrode (Transparent Conductive Oxide, TCO) plays a decisive role in CIGS solar cell manufacturing.

To achieve a good absorption of sunlight and a good transmission of electricity simultaneously, the TCO layer requires a good light transmission and a high electric conductivity. The latest equipment generation of FHR Anlagenbau achieves excellent layer characteristics: For 1000 mm wide TCO layers remarkably low specific electrical resistivities of 5 × 10-4 Ohm × cm at a high transmission rate of 87 % are achieved. For comparison only: uncoated glass panes offer a transmission of approximately 92 %.In addition to foil coating solutions for the photovoltaics industry FHR Anlagenbau presents on this year’s EU PVSEC in Frankfurt/Main its product portfolio in the field of sputter targets and inline production plants.