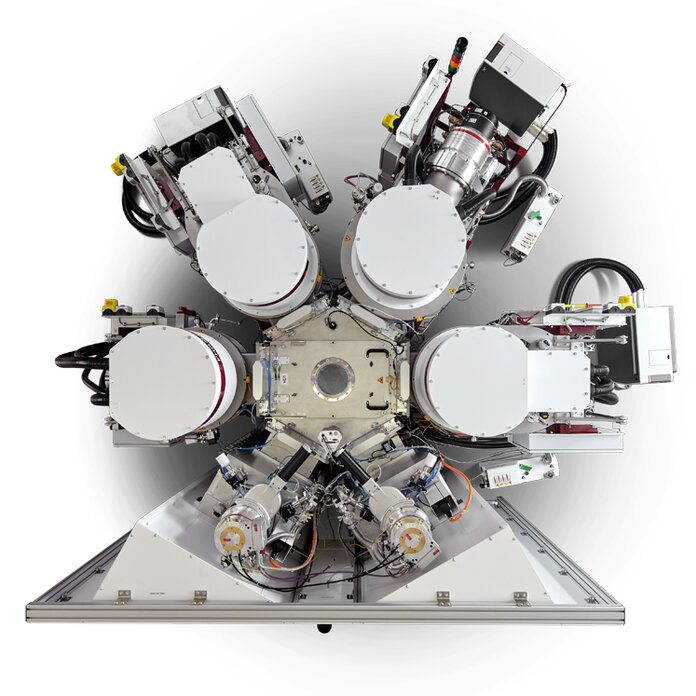

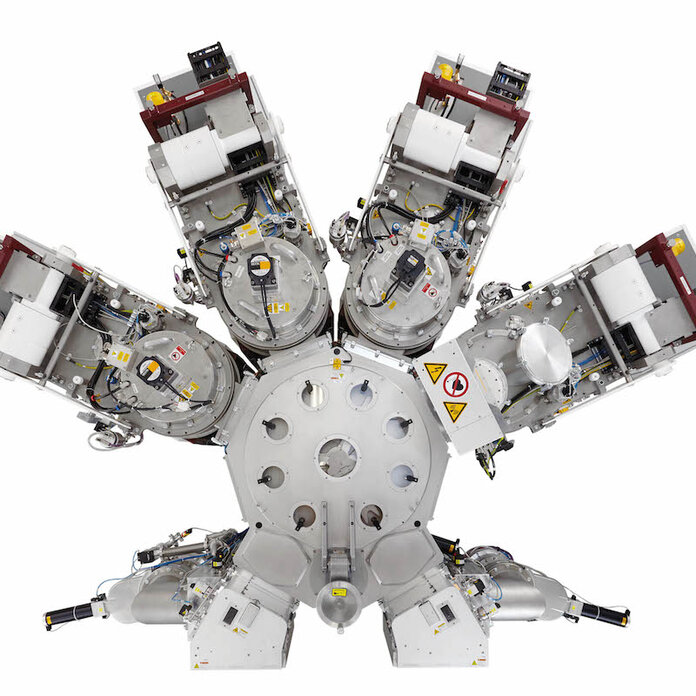

Freely Configurable Cluster Systems

FHR.STAR Product Range

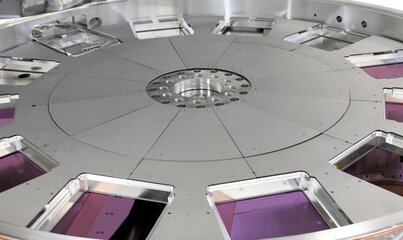

- Proven, flexible modular concept with central transfer arm handling

- Diverse technological processes

- Handling as a single substrate or in a carrier

- Manual loading or automatic handling from the magazine

- Clean room connection possible

Thin film coating systems for handling a wide variety of substrates – such as plates, disks, wafers or highly delicate applications, such as needles or pins. Be it layer deposition, pre- or post-treatment: with the combinable modules of the STAR series, a wide range of tasks can be mastered in research and development, pilot production or the processing of small to medium-sized series.

- Microelectronics

- Printed circuit boards

- Sensors

- Display

- OLED

- Thin film solar cells

- Thin film batteries

- Filters

- and much more

An advanced modular system with numerous variation options, maximum flexibility in the configuration of the individual modules, numerous intervention options via our in-depth formula editor: These and many other features make our vacuum processing systems from the FHR.Star product range the #1 choice for R&D applications at the cutting edge of research.

In addition, FHR.Star systems are ideally suited to solving tasks in the microelectronics and semiconductor industry thanks to their stringent design for standard wafers.

The choice is yours: With our FHR.Star product range, we can draw on a broad spectrum of previously implemented systems and compile a suitable system for you. Or we can work with you to develop your own customized configuration.

The following technologies are available for use in our FHR.Star systems:

- Plasma etching/Pre-cleaning

- Magnetron sputtering

- Thermal evaporation

- Electron Beam Evaporation (or “E-Beam Evaporation”)

- Atomic layer deposition (ALD & SALD)

- Heat treatment

We will be happy to discuss deviating processes with you personally!

With the systems in FHR.Star product family, our customers acquire high-quality coating systems that combine quality, variability and reliability.

- Maximum flexibility thanks to modular system concept

- Customized configuration according to customer requirements

- Effective use of space thanks to variable arrangement

- Adjustable target-substrate distance

- Quick and easy target change

- Substrates in typical wafer sizes

- Fully automatic process control

- Attractive investment and operating costs

Your Contact Person

Do you have any questions?

Would you like to know more about our FHR.Star product range? Our expert, Matthias Rödl, will be happy to help you. Get in touch with us.

Vacuum Coating Systems

OTHER PRODUCT SERIES

Product Enquiry

You would like to learn more about our product? We are at your disposal. Contact us today to request detailed information, ask questions or receive individual advice.

Your interest is important to us, and we look forward to hearing from you!