VACUUM COATING SYSTEMS

Are you looking for the optimum vacuum coating solution for your project?

Our systems are the perfect choice for you.

PROVEN COATING SOLUTIONS

Thin and ultra-thin functional coatings must fulfill the highest requirements during the deposition process. We offer you reliable coating solutions with our tried-and-tested systems.

Our portfolio includes both tried-and-tested modular coating systems and specialized systems tailored to your individual requirements – we have been your experts in the manufacturing of vacuum coating systems for more than 30 years.

Our Vacuum Coating Systems

OUR FHR PRODUCT RANGES AT A GLANCE

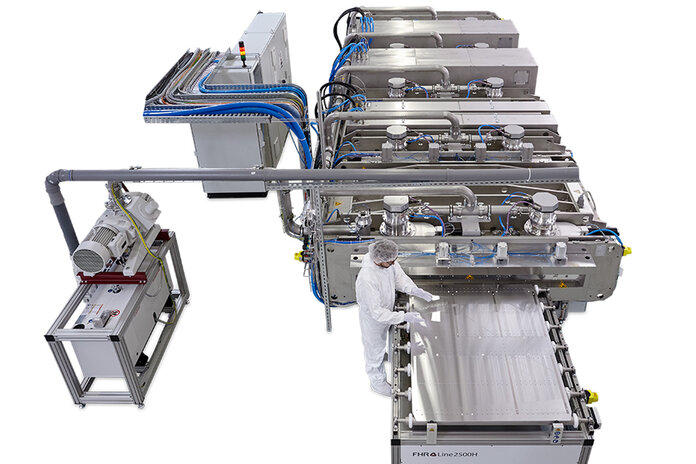

Precision Sputter Coating Systems for Interference Optics Applications

FHR.STAR-EOSS® Product Range

- For coating filter glasses, lenses, mirrors and much more.

- For coating thin glass and thick glass

- With magazine airlock

- Sputter-up process for particle minimization

Thin film coating systems for the development and production of precision optics.

- Band-pass filters

- Anti-reflective coatings

- Highly reflective coatings

- Beam splitter

- Notch filter

- and much more

The systems of our FHR.Star-EOSS® product family are based on customer requirements for a precision sputtering system for the deposition of optical multilayers involving the highest demands in terms of layer quality and layer thickness homogeneity on predominantly flat and even substrates.

Our precision sputtering systems are suitable for the deposition of interference-optical layer systems for the production of dielectric mirrors and optical filters – such as bandpass filters or multi-notch filters.

The system concept represents a joint development with the Fraunhofer Institute for Surface Engineering and Thin Films, which was designed as an Enhanced Optical Sputtering System (EOSS®). During further development efforts, particular emphasis was placed on coating quality, process stability, productivity, ease of maintenance and the ability to coat larger substrates. The layer growth is monitored in-situ by optical broadband monitoring.

With an EOSS® system, you are purchasing the most advanced product currently available on the market for this application.

The system has the following advantages over the competition:

- Extremely low particle count thanks to sputter-up process

- Optimal layer growth through bipolar-controlled double sources

- Highest material utilization and longest target service life through the use of tubular cathodes

- Precise layer thicknesses can be achieved by means of time-controlled deposition and optical broadband monitoring

- Optional automatic system tracking to correct the shift design

- A design uncompromisingly geared towards production processes

- Up to four coating compartments can be used

- One or two plasma sources can be used

- Large substrate carriers for universal adaptation of the substrate holder

- Multiple process runs possible

- Quick and easy maintenance accessibility

- Comprehensive and easy-to-use software interface

Your Contact Person

Do you have any questions?

Would you like to know more about our FHR.Star-EOSS® product range? Our expert, Ralf Pohl, will be happy to help you. Get in touch with us.

Vacuum Coating Systems

OTHER PRODUCT SERIES

Product Enquiry

You would like to learn more about our product? We are at your disposal. Contact us today to request detailed information, ask questions or receive individual advice.

Your interest is important to us, and we look forward to hearing from you!

LOOKING FOR A SPUTTER TARGET?

We develop and manufacture sputtering targets up to 4000 mm target length as required – both in large series and as individual items.

FHR – The Right Partner at Your Side

Shaping the future together – with reliable and high-quality coating solutions from FHR:

- Industry-leading quality: Our vacuum coating systems are designed for maximum precision and durability.

- Customized solutions: We offer individual solutions for your coating project that meet your specific requirements.

- Innovative methods and technologies: With our many years of experience and expertise in vacuum coating, we continue to set new standards.

- Dedicated customer service: Our experienced team is always available to answer your questions and provide you with support in your projects.

Discover the diverse range of possibilities with our vacuum coating technology, and place your trust in FHR as your reliable partner for outstanding coating solutions. Please feel free to get in touch with us to find out more and realize your projects together.

Your Contact Person

Do you have any questions?

Would you like to know more about our vacuum coating systems? Our Director of Product Management, Sven Häberlein, will be happy to help you. Give us a call or write us a message.